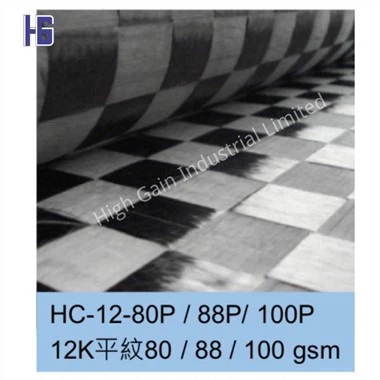

Aramid Fiber Fabrics

Aramid fiber, fully known as "polyphenylene terephthalamide", has excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid resistance, alkali resistance, light weight, etc. Aramid fiber was successfully developed and commercialized by DuPont Kevlar Fabrics in 1960 s. Therefore, before the emergence of carbon fiber, Aramid fiber has always occupied the high-performance fiber market.

Specialties:

1/ High impact resistance and crack resistance

Aramid fiber has excellent impact resistance, and because it is tough and can absorb a lot of energy, it will not crack under pressure. It is widely used to manufacture armor for bulletproof vests, ships, kayaks and military vehicle parts. The impact resistance of aramid fiber composite is 5 times that of carbon fiber composite (measured by drop hammer impact method). This extraordinary anti impact or anti bullet ability is caused by the formation of long atomic chains with aramid structure.

In view of the excellent impact resistance, aramid fiber is widely used to make bulletproof vests and tank armor materials for military purposes. The bulletproof vest is usually made of dozens of layers of aramid (such as Kevlar), and includes a ceramic plate between the two layers. The protective cover used by some armored vehicles (such as American M1 tank) is made of steel aramid steel material, which can resist anti tank missiles with a diameter of 700 mm.

2/ Low density/low weight

Aramid fiber has a very low weight, which is an advantage in manufacturing composite materials. Although carbon fiber composites are considered to be very light, aramid fiber composites are about 20% lighter than carbon fiber composites. The use of aramid fabric in composites can increase impact resistance and wear resistance, and reduce the weight of composite components.

The density of aramid fiber is about 1.45g/cm ³, The density of aramid/epoxy composite is about 1.3g/cm ³. The calculation is based on epoxy resin and curing agent~1.1g/cm ³ And the advanced technology used in the production of composite materials, namely autoclave prepreg. The density of carbon fiber composites, which are generally considered to be very light, is close to 1.55g/cm ³, In general, aramid fiber composites are 20% lighter than carbon fiber composites.

How to compare the weight of aramid fiber composites and metals? 2.7g/cm for aluminum ³, 4.5 g/cm for titanium ³, 7.9g/cm for steel ³, Therefore, aramid fiber composites are 2 times lighter than aluminum, 3 or 4 times lighter than titanium, and 6 times lighter than steel.

3/ Moderate stiffness, between glass fiber and carbon fiber

Aramid fiber composites have higher stiffness than glass fiber composites, but also significantly lower than carbon fiber composites. Aramid fibers are similar to carbon fibers. There are many types of fibers, including standard, medium and high modulus fibers, which can provide different stiffness and strength.

The stiffness of different types of fibers is as follows:

Glass fiber fabric - from 72 GPa (standard E-glass) to 87 GPa (S-reinforced glass fabric);

Carbon fiber fabric - from 230GPa (Toray T300) to 588GPa (Toray HM grade M60J);

Aramid fabric - from 96GPa (Kevlar 129 for standard aramid) to 186GPa (Kevlar 149 for aircraft/aviation industry).

In conclusion, the stiffness of aramid composites made of standard fabrics is 30-40% higher than that of glass fiber composites and 50% lower than that of carbon fiber composites

4/ Abrasion resistance

Aramid fiber composites have been widely used in wear prone parts, such as skid plates to protect racing engines. Aramid is usually used in the extraction industry (such as mining industry) to reinforce the rubber belt of conveyor belt and ensure higher strength and wear resistance. According to Kevlar manufacturer, the wear resistance can be improved by 50-70% after reinforcement. Because of these characteristics, the material can be used for composite materials and work clothes, such as cutting resistant safety gloves using aramid fabrics, such as Twaron or Kevlar.

5/ Low dielectric constant

The dielectric constant of aramid fiber composite material is as low as~3.85 (10 GHz), ensuring the good performance and strength of signal penetrating aramid protective cover/radome. This antenna is widely used for military purposes, such as on military aircraft.

Aramid fiber used in military radome

The aramid fiber composite housing/radome can protect the antenna from damage and ensure good signal performance. In contrast, E-glass fiber composites provide a permittivity corresponding to 6.1 (10 GHz), resulting in a 60% reduction in antenna signal power and performance. In addition to aramid fiber, quartz fiber is also used, and its dielectric constant is 3.78 (10 GHz).

6/ Other features

Aramid fiber has low thermal expansion characteristics, which is very stable at high temperatures, almost zero. The thermal expansion coefficient is slightly negative, equivalent to (- 2.4 x 10 ⁻ ⁶/° C). Aramid fiber is a good insulator and does not conduct electricity.

A special property of aramid fiber composites is related to vibration absorption, so it can be used to manufacture vibration bearing components, such as aircraft structural components.

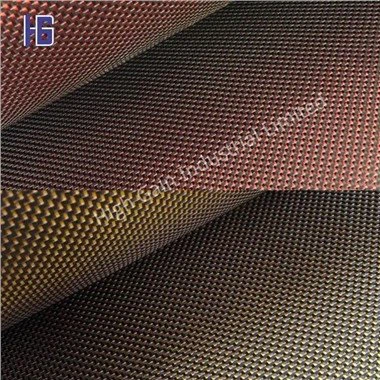

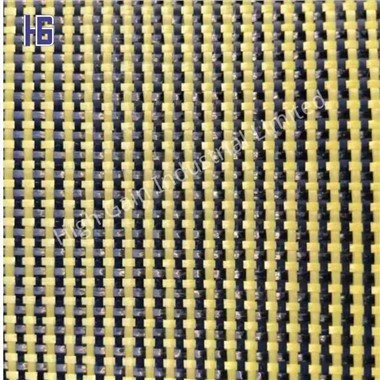

Aramid can weave with carbon fiber or fiberglass to form carbon fiber aramid fabric or fiberglass aramid fabrics which can maximize the advantages of 2 types of fiber.

Hot Tags: aramid fiber fabrics, China aramid fiber fabrics manufacturers, suppliers, factory, aramid fiber material, aramid fiber sheets, Carbon Fiber UD Fabrics, Aramid woven fabric, twill carbon fiber prepreg, ultra high molecular weight polyethylene fiber composite

Previous

3D Triaxial Carbon Fiber FabricYou Might Also Like

Send Inquiry