What Carbon Fiber Prepreg Is

Carbon fiber prepreg refers to a composite material that is made up of carbon fibers that are impregnated with a resin matrix. The term prepreg is short for "pre-impregnated," meaning that the carbon fibers have already been saturated with resin prior to their use in the manufacturing process. This composite material is widely used in aerospace, sports, automotive, and defense applications due to its unique properties.

Carbon fiber is a lightweight and strong material that offers superior strength-to-weight ratio and stiffness compared to traditional materials like steel, aluminum, and wood. For this reason, carbon fiber composites are the material of choice in various applications where weight reduction and high strength are key factors. However, carbon fiber alone cannot be used in its raw form since it lacks rigidity and is too brittle to be used as a structural material. Hence, a binding material is needed to hold the carbon fiber together and provide rigidity and structural support.

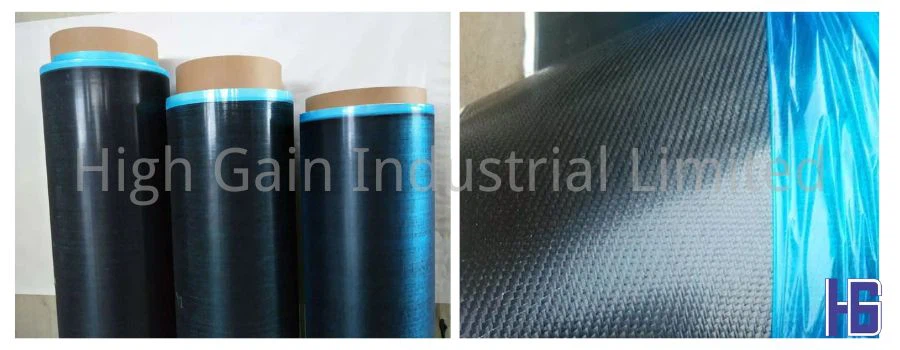

Prepregs are manufactured by first impregnating the carbon fiber with a resin matrix, typically an epoxy resin, to achieve a uniform distribution of the resin throughout the carbon fiber. The resin is initially in a semi-solid state, which enables easy handling during the manufacturing process. The impregnated carbon fiber is then rolled onto a flat surface to form a sheet, which is stored at low temperatures to prevent the resin from curing prematurely.

The prepregs are stored in refrigerated conditions to maintain the state of the resin. The cooling process slows down the curing of the resin, which gives the prepreg an extended shelf life. The different types of resins used in the prepreg manufacturing process can be classified based on their curing mechanism, i.e., thermosetting and thermoplastic resins.

Thermosetting resins such as epoxy, phenolic, and polyester resins are the most commonly used in the prepreg manufacturing process. These resins are cured through a chemical reaction that occurs due to the addition of heat or pressure. The curing process results in a rigid and stable composite material that can withstand high mechanical loads.

Thermoplastic resins such as polyetherimide (PEI), polyamide (PA), and polyetheretherketone (PEEK) are also used to manufacture prepregs. Unlike thermosetting resins, thermoplastic resins can be melted and reformed multiple times, which makes them suitable for use in applications that require a high degree of flexibility, such as drones and satellite structures.

Carbon fiber prepregs offer several advantages over traditional materials such as steel and aluminum. Carbon fiber composites are less dense than steel and aluminum, which makes them ideal for applications that require lightweight yet strong materials. They also offer a higher stiffness-to-weight ratio, which means they can withstand greater loads without bending or deforming. Additionally, carbon fiber composites are corrosion-resistant, which makes them ideal for use in harsh environments.

In summary, carbon fiber prepreg is a composite material that is made up of carbon fibers impregnated with a resin matrix. It offers excellent strength, stiffness, and weight reduction properties, making it an ideal material for aerospace, sports, automotive, and defense applications. The manufacturing process involves impregnating carbon fibers with a resin matrix and rolling them into sheets, which are stored at low temperatures to prevent premature curing of the resin. Different types of resins can be used, depending on the application requirements. Carbon fiber prepregs offer several advantages over traditional materials, making them a popular choice for many applications.